Palletizing Systems

As for most manufacturing settings, finished goods need to be shipped safely and securely on pallets. Palletizing machines and equipment automate the task for you, lifting and moving heavier loads, all while keeping your product and personnel safe.

These systems generally use a series of integrated conveyors, vision technology, mechanical, or even robotic solutions to accomplish the task automatically. And with benefits such as fewer workplace injuries, increased production, and lower costs, it’s important to consider a modern palletizing system.

Recent advances in palletizing systems have greatly improved their efficiency and the speed at which they operate. For instance, robotic palletizing systems are now available and offer improved performance over conventional systems. If you are still palletizing by hand or using an outdated palletizing cell, you owe it to yourself to examine the benefits of modern systems.

Automatic Palletizing Systems

Many automatic palletizing systems are intelligent and interface with warehouse execution systems (WES). They handle large volumes and are able to work tirelessly around the clock in harsh environments. Automatic palletizers also streamline the entire process, minimize labor and transportation costs, and reduce product damage. They are more accurate than manual handling and are scalable to meet future demands.

Conventional Palletizing Systems

Conventional palletizing systems have been used for more than 50 years. Typically fed by an inline conveyor, the product enters the palletizing cell using a series of turners to ensure the product is oriented to accommodate a specific load pattern design. Built in subsequent layers via a load forming table, the product layer is slid into position creating a series of tiers to build the load on top of the pallet. Since it uses accumulated product in succession to build these layers, conventional palletizers tend to take up more footprint within a facility. With that being said, this type of system is ideal for operations with high volumes and fewer SKUs.

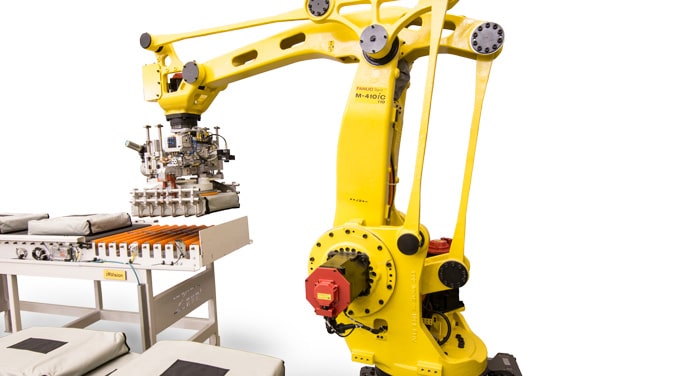

Robotic Palletizing Systems

More modern palletizing cells use robotics to take palletizing to another level. Robotic palletizing systems are flexible enough to manage a wide assortment of product types with more efficiency than conventional systems. This is because they’re capable of securing, lifting, orienting, and placing products in a single lift using the robot’s flexible axis, rather than bumping or sliding products on the conveyor or layering tables.

Robotic palletizing systems are programmable for maximum flexibility and SKU variety. This means the scalability and flexibility of these cells allow for future demands. Maybe production volumes increase or product sizes change – assuming you’re operating within the capabilities of the system, this is a simple programming change, rather than adaptations made to mechanical components of a conventional cell.

Palletizing System Solutions from Ambrose

Automatic palletizing systems can greatly increase your end of line production and automate hazardous jobs, thereby reducing on-the-job injuries and downtime. If you want to explore or upgrade your palletizing process, contact one of our product experts today, and we will be happy to help you identify the right palletizing solution for your operation.

How to buy:

It’s our goal that you’re completely satisfied with the purchase of your equipment. Therefore, we will work together to determine the optimal options, supplies, installation methods, and training that best serves your application, budget and quality standards.

Speak to a Representative – Call (913) 780-5666 or email AmbroseCRT@ambroseco.com Fill out a quote request online.